ribbon mixer / batch / solid/liquid / vertical

ribbon mixer / batch / solid/liquid / vertical

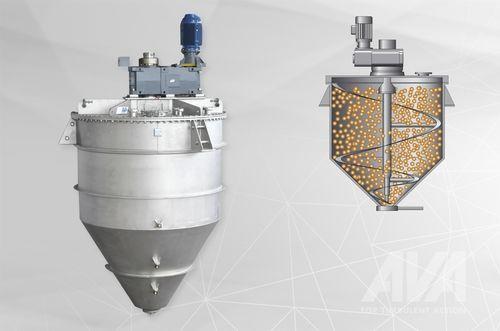

20 – 80000 l | HVM series

INO Group

-

Type:

ribbon

-

Batch/continuous:

batch

-

Applications:

solid/liquid

-

Other characteristics:

vertical, conical

-

Associated function:

clean-in-place (CIP)

Useful volume 20 – 80.000 liters

Fields of application

The cylindrical conical mixer is used for coating and homogenizing of bulk solids through to evaporating suspensions.

System with many advantages

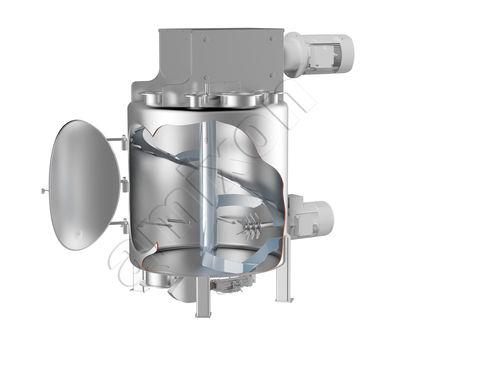

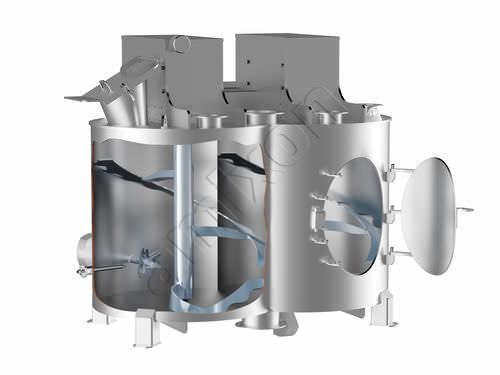

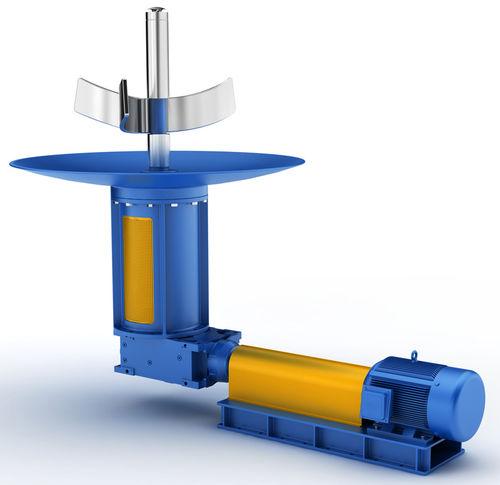

Compared to other vertical mixing systems, the HVM range achieves higher mixing efficiency with a considerably reduced construction height. The HVM cylindrical mixer / cylindrical dryer combines the advantages of a conical vessel, e.g. regarding to an optimum discharge, with the optimized overall height, in order to fit into existing buildings etc.

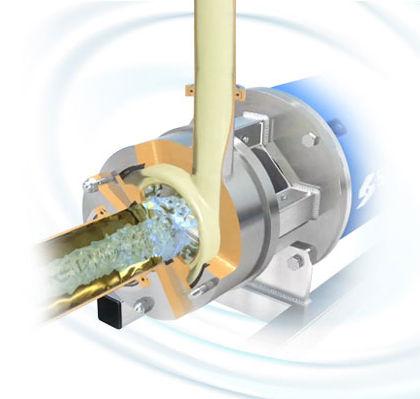

The rotating AVA mixing helix (available in single or double execution) conveyers the product upward, along the vessel wall. From here, it drops down into the shaft area at the center of the vessel and is again a part of the mixing process. The mechanical transmissions are located outside the vessel. Contamination of the product with oil or lubricating grease, which is a common problem within other mixing systems, is excluded by this technology.

The cylindrical mixers in the HVM range are emptied on bottom-side with the agitator rotating. This ensures a residueless discharge, guaranteed in particular with the conical base. Optimum accessibility is assured due to the large inspection doors in the cylindrical area of the vessel, whilst easy cleaning is automatically effected by the integrated CIP nozzles.

In the HVM-dryer variant the vessel wall and / or agitator are fully heated, meaning that an above-average thermal transfer coefficient is achieved. The configuration comprising a cylindrical dryer with flat base is particularly efficient in terms of drying behavior.